|

|

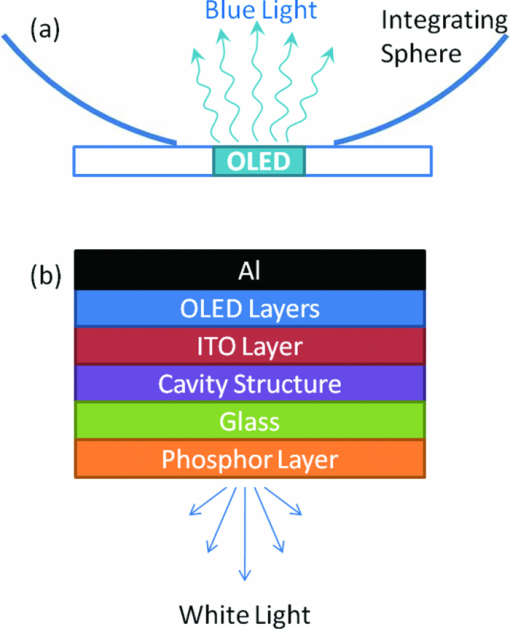

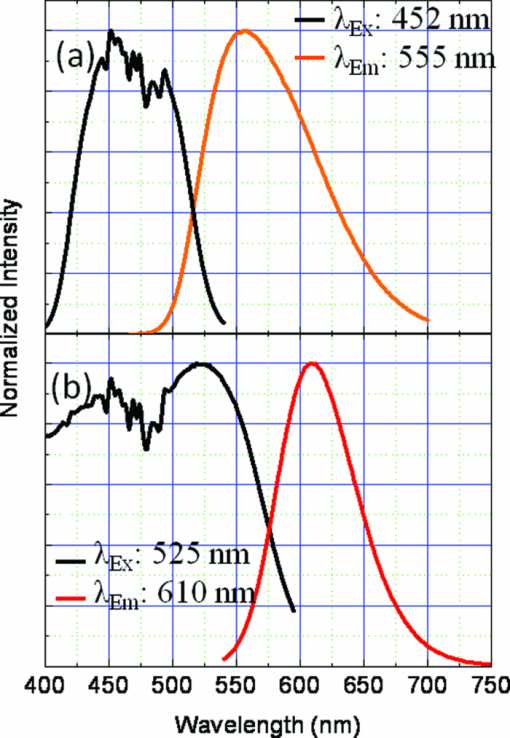

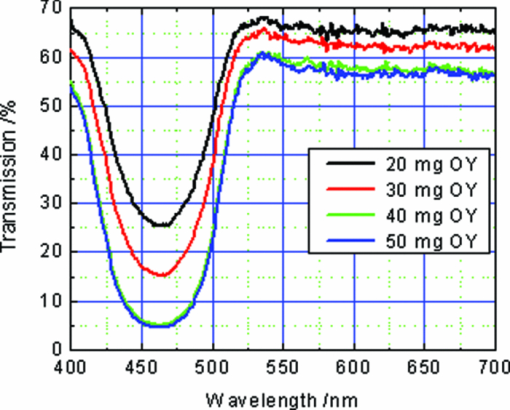

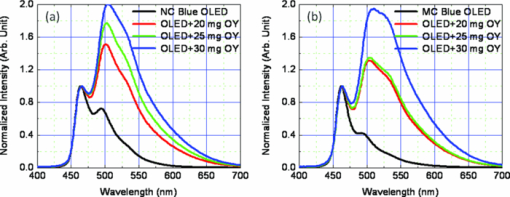

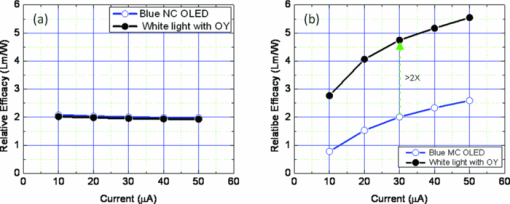

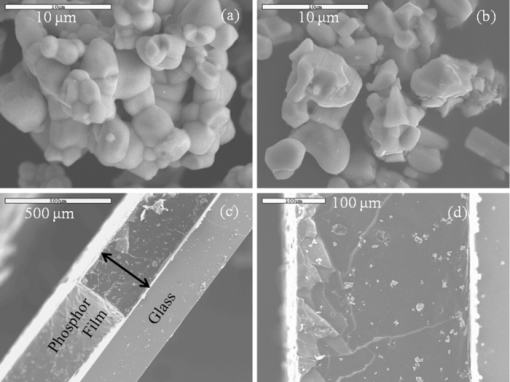

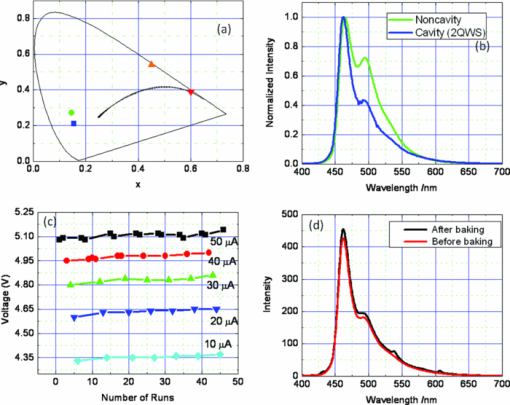

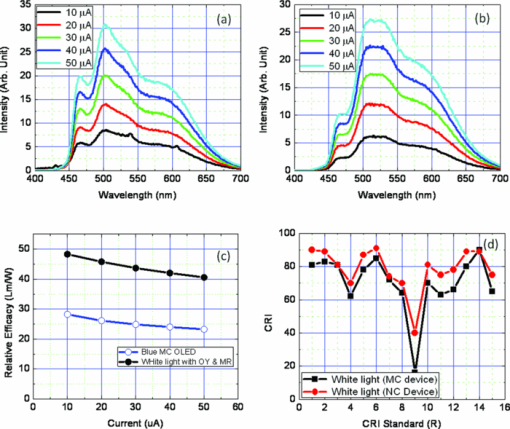

1.IntroductionThe light-emitting diode (LED), an emerging and energy efficient lighting technology, is expected to significantly reduce global energy consumption and green-house emission.1 By using white LEDs, the Department of Energy recently has put forward a target to reduce the total household lighting energy usage by 50% by 2025. Currently, a tremendous amount of effort has been directed toward research on two types of white LEDs: 1. intrinsically generated white light from LEDs and 2. down-conversion of high energy light to white using a phosphor layer. The intrinsically generated white light from the LED is produced from a single or multi-emitting layered LED device,2, 3 whereas a down-converted white light is generated from the LED with single or multiple phosphor/s. An ultraviolet (380 to 400 nm)4, 5, 6, 7 or a blue (440 to 480 nm) light8, 9, 10, 11 is generally used for the down-conversion. For the blue light-based down-conversion studies, an organic LED (OLED)12, 13, 14 or an inorganic LED (iLED)15, 16, 17, 18 are used where a fraction of blue light is absorbed by the phosphor layer and re-emitted as lower energy photons. The combination of the blue and the lower energy photons produces white light. Use of the OLED blue devices is advantageous to develop large area white light emitting devices for use as general purpose lighting and backlights for liquid crystal display. This research is focused on optimization of the down-conversion phosphor layer for efficient and high quality white light emission using the blue OLEDs. This includes characterization of phosphors, phosphor films, and film-incorporated devices to enhance the luminance efficacy and quality of white light. In this research, combinations of blue emitting OLEDs and yellow phosphor or mixture of yellow and red phosphors for the down-conversion studies were used. We optimized the film thickness and phosphor loading to increase out-coupling efficiency of white light. The optimized device showed a two times improvement in luminance efficacy for white light compared to blue luminance. A combination of yellow and red phosphor exhibited a high quality white light. 2.Experimental2.1.Preparation of Phosphor Films on GlassYellow (OY) and red (MR) phosphors were acquired from two commercial vendors. The yellow emitting OY phosphor is a cerium doped yttrium gadolinium garnet-based phosphor, whereas the red emitting MR phosphor is based on europium doped nitrido silicate. For preparation of phosphor thin-films, a silicone gel (LS-3354, NuSil Technology) was used as a matrix. The silicone gel (viscosity: 5400 cP) was prepared by mixing two uncured parts of transparent gels at a weight ratio of 1:1. The refractive index of the film was found to be a slight function of wavelength (1.577 at 411 nm to 1.547 at 589 nm). To optimize the loading of phosphor in silicone, films were prepared by varying the weight of the phosphor(s) in 150 mg of silicone gel. The films were prepared with 20, 30, 40, or 50 mg of OY phosphor in silicone. Similarly, the OY and MR red phosphor mixture at a weight ratio of 2:1 in silicone was used to prepare yellow-red phosphor film samples. Our previous results19 showed that the weight ratio of 2:1 for yellow to red phosphor yielded an average color rendering index (CRI) or Ra value of 90 when excited at 460 nm. The phosphor-silicone gel mixtures were manually doctor-bladed onto the glass substrates (25 mm × 25 mm) followed by curing the film at 70°C for 1 h in an oven. The curing of the films also facilitates a large range of operating temperatures: −40°C to 200°C. 2.2.Characterization of Phosphor and Phosphor FilmsFor particle size and morphological analyses of the phosphor, a scanning electron microscope (SEM JEOL JSM 6400) was used with an accelerating voltage of 15 kV. The phosphor dispersed films were also characterized by the SEM. Photoluminescence (PL) and photoluminescence excitation (PLE) spectra were acquired using a JASCO spectrophotometer (FP6500). The spectrophotometer also has a 60 mm diameter integrating sphere and the combination was used to characterize optical properties of films, light sources, and white light. Transmission characteristics (400 to 700 nm) of films, International Commission of Illumination (CIE) color coordinates of sources, phosphors and white light, internal quantum yield (QY) of phosphors, and CRI values of white lights were evaluated or determined using the spectrophotometer. For the QY measurement of phosphor, a blank substrate (cured 150 mg silicone without phosphor) and a sample with 30 mg of OY or MR phosphor and 150 mg silicone were used. Thickness of the phosphor films was measured using a profilometer (Tencor P2 Long Scan) at four different spots on a diagonal scratch. For the OLED characterization, the power was supplied by a Keithley power supply (2400 Sourcemeter). The OLED with or without phosphor film was placed flush with an aperture of the integrating sphere to collect the light [see Fig. 1]. The luminance values were acquired from the phosphor-loaded and the blank films at different operating powers. For down-conversion studies, silicone gel-phosphor mixtures were directly deposited on the glass-side of the OLED followed by curing in the oven at 70°C for 1 h. A schematic structure of a down-conversion device is illustrated in Fig. 1. The structure of the OLEDs is discussed in Sec. 3.4 in detail. 3.Analysis and Optimization3.1.Particle and Film AnalysisThe SEM micrographs of as-received OY and MR phosphor particles are shown in Figs. 2, 2, respectively. For the OY phosphor, the size distribution of individual particles ranges from 0.5 to 10 μm. The agglomerated size was found to be as high as 50 μm. For the MR phosphor, the particle size distribution is almost the same as with the OY phosphor. However, the largest agglomerated particle size is smaller (∼25 μm) than the OY phosphor. Fig. 2SEM micrograph of (a) OY yellow phosphor, (b) MR red phosphor, and (c) cross-section of a phosphor film prepared using 30 mg of OY phosphor and 150 mg of silicone. (d) A higher magnification view of the film shown in (c).  Figure 2 shows a cross-section of a phosphor film prepared using 30 mg of OY phosphor in 150 mg of silicone on a glass substrate. A higher magnification micrograph [Fig. 2] of the cross-section shows that the individual phosphor particles of ∼5 μm and agglomerated particles of >20 μm are well dispersed throughout the film. Approximately 60% of the particles are present in agglomeration. The thickness of the 30 mg phosphor in 150 mg silicone film was 230 μm. The average thickness measured by a profilometer showed a value of 220 μm. The thicknesses of several other films with weight of the phosphor from 20 to 50 mg in 150 mg of silicone were measured by the profilometer and the average thickness of the films was found to be in the range of 210 to 240 μm. 3.2.Optical PropertiesFigure 3 shows the PL and PLE spectra of the OY [Fig. 3] and MR [Fig. 3] phosphors. The PL peaks of the OY and MR phosphors were centered at 558 and 610 nm, respectively. As mentioned earlier, the hosts of the OY and MR phosphors are oxide and nitride, respectively. Note that the PLE spectra of the MR phosphor is broader (400 to 575 nm) compared to that of the OY phosphor (400 to 525 nm). The difference of the PLE bands arises from two different hosts. Figure 3 shows that the PLE spectrum of the MR phosphor is broad compared to that of the OY phosphor, but also a significant part of the PL spectrum of the OY phosphor overlaps with the PLE peak of the MR phosphor. In other words, the absorption of the MR phosphor extends to longer wavelengths than the OY phosphor. The QY of the OY and MR films were found to be 89% and 84% at an excitation of 460 nm, respectively. The CIE coordinates were (0.45, 0.54) and (0.60, 0.39) for the OY and MR phosphors, respectively. 3.3.Transmission Study of FilmsFor transmittance measurements, samples were placed on an aperture of the integrating sphere to collect all of the transmitted light. Transmission data showed that silicone did not absorb light in the visible region. However, with an increased weight of the phosphor in the silicone matrix, the transmission gradually decreased. Figure 4 shows the percent transmission versus wavelength from the films with different weight of the OY phosphor in 150 mg of silicone. Approximately 60% to 65% and 65% to 70% transmission were observed from the samples containing 30 and 20 mg of phosphor in matrix, respectively. For 40 and 50 mg of phosphor film samples, the transmissions decrease to 55% 60%. The trough in the transmission between 400 and 525 nm in Fig. 4 is due to absorption of light by the phosphor. The transmission values were reduced between 525 and 700 nm probably due to optical scattering by the phosphor particles. Since 20 and 30 mg OY phosphor in silicone shows more than 60% transmission, these phosphor mixtures will be used for the down-conversion study. 3.4.Characteristics of OLEDTwo types of blue emitting OLEDs were used in this study: noncavity (NC) and microcavity (MC). The NC device contained no dielectric mirrors20 in between the indium doped tin oxide (ITO) and glass substrate [see Fig. 1], whereas the MC devices contained two (2QWS) or four layers of quarter wave stacks in between the ITO layer and glass. The structure of devices was ITO 50 nm//poly (3,4-ethylene-di-oxy-thiophene)–polystyrene-sulfonic acid (PEDOT:PSS) 60 nm//1,1-bis[(di-4-tolylamino) phenyl] cyclohexane (TAPC) 25 nm//N,N′-dicarbazolyl-3,5-benzene (mCP) with 20 wt.% iridium (III) bis [(4,5-di-fluorophenyl)-pyridinato-N, C2′] picolinate (FIrPic)//4,7 diphenyl-1,10 phenanthroline and tris [3-3-(pyridyl)-mesityl] borane (3TPYMB) 40 nm//CsCO3 0.8 nm//Al 100 nm. The active area was 2 mm × 2 mm for all the OLED devices. See Refs. 20 and 21 for a detailed device structure and the fabrication process of the OLEDs. In this discussion, we have used data from NC and 2QWS MC blue emitting devices. The OLED device with NC exhibited a nearly Lambertian emission while 2QWS OLEDs have a more directional emission. We previously reported22 that down-converted light from a highly directional blue emitting inorganic LED could yield a factor of 2 times enhancement in luminance efficacy. The emission peaks from both NC and MC OLEDs were well within the broad peak of the PLE spectra of the phosphors (Fig. 3), therefore the blue light from the OLED was partially absorbed by the phosphor/s and down-converted to yellow or yellow-red light. The CIE coordinates of the OLED devices with cavity and noncavity structures were (0.154, 0.211) and (0.145, 0.271), respectively [see Fig. 5]. Figure 5 shows the emission characteristics from the two types of OLEDs. The macrocavity structure shifts the broader electroluminescence emission of FIrPic-doped OLED to a narrow blue emission. As mentioned earlier the microcavity-based devices produce more directional emission compared to the noncavity devices. Therefore, down-conversion efficiency can be enhanced. Degradation of the OLED was studied over a range of current from 10 to 50 μA (size of active area of every device: 2 mm × 2 mm) for several consecutive runs as shown in Fig. 5. No degradation of the OLED device occurred over 60 consecutive runs (∼1 min/run). However, a device operated at 1 mA degraded by ∼6% during every run. Baking of the OLED device at 70°C for 1 h caused an improvement of luminescence properties. Figure 5 shows electroluminescent spectra from the 2QWS device before and after baking of the device. Baking of polymer LEDs or PLEDs is reported to reduce the amount of radical ions generated during interactions of polymers. These ions quenched the luminescence from the devices.23 Heat treatment of a vapor deposited organic film at higher temperature caused a higher crystallinity and higher carrier mobility as compared to an as-deposited film.24, 25 Data from this study suggest that better crystallinity improved the device performance. Fig. 5(a) Color diagram and CIE coordinates for the OLEDs (round spot: noncavity and square spot: 2 quarter wave stack microcavity) and phosphors (triangle: OY yellow and inverted triangle: MR). (b) Emission spectra from the two types of OLED: noncavity and microcavity with 2QWS structure. (c) Voltage across the device to achieve various currents versus the number of runs showing no degradation (active area: 2 mm × 2 mm). (d) Emission from an OLED before and after baking.  3.5.Phosphor Optimization with OLEDsBoth MC and NC OLEDs were tested either bare or integrated with phosphor coated glass slides for down-conversion to white light. In down-conversion, yellow or yellow-red light from the phosphor(s) mixed with nonabsorbed blue light from the OLED to provide white light. The schematic in Fig. 1 illustrates the configuration of the OLED and integrating sphere for measurements of all the photons emitted at all angles. Since the 20 and 30 mg sample showed better transmission as compared to the 40 and 50 mg OY phosphor film (see Fig. 4), three phosphor films were prepared by mixing 20, 25, or 30 mg of the OY phosphor in 150 mg of silicone on three ∼20 μm thick glass slides. After collecting five emission spectra from each bare blue OLED at currents from 50 μA, the same devices were combined with a phosphor layer and characterized for down-conversion of blue to white light. Each phosphor film was integrated with the NC or MC OLED using a glass index-matching-gel. Figures 6, 6 show normalized emission spectra (∼465 nm) from bare and phosphor integrated NC OLED and MC OLED at a current of 50 μA. Figure 6 shows that the emission peak from phosphor increases with an increasing amount of phosphor in the film. Nonnormalized down-converted spectra showed that the blue emission decreased and emission from the phosphor increased with an increased amount of phosphor. Accordingly, the CIE coordinate shifts linearly from left to right in the CIE diagram with an increasing amount of the OY phosphor in the film: (0.231, 0.442), (0.244, 0.465), and (0.26, 0.485) for the 20, 25, and 30 mg phosphor integrated NC device, respectively. The CRI values were found to be less than 45 for all samples. For the phosphor integrated MC device, the CIE coordinates also followed the same trend as with NC devices. The CIE coordinates were (0.247, 0.445), (0.251, 0.45), and (0.274, 0.492) for 20, 25, and 30 mg of phosphor, respectively. The CRI value is in the range of 45 to 50. The white light from MC device exhibits better CRI values due to a larger FWHM of the emission peak compared to the NC device (see Fig. 6). Nevertheless, the 30 mg of phosphor in 150 mg of silicone exhibited a better quality of white light as compared to 20 and 25 mg phosphor films. Therefore, the calculated efficacy will be compared for the 30 mg phosphor layers. 4.Down-Conversion Study4.1.White Light Using Yellow PhosphorsFigures 7, 7 show the relative efficacies (lumens per OLED input Watt) versus driving current to OLEDs for blue and down-converted white light from noncavity and microcavity devices, respectively. The efficacy values were compared in between bare blue and down-conversion white using a photopic response curve. The absolute efficacy value of down-conversion was calculated to be 32 lm/W, whereas the bare blue emission was found to be 38 lm/W at 100 cd/m2 (Ref. 26). Similarly, a relative efficacy, as shown in Fig. 7, shows no improvement in down-converted white light from NC-OLED blue emission at different bias to the OLED devices. As reported above, the NC devices exhibit more Lambertian emission as compared to MC devices. We also reported above that directional blue emission enhances the luminance efficacy by more than a factor of 2 for yellow emitting phosphors. The data for MC devices show that the efficacy for the down-converted white light was 2 times higher than that of the blue light from a bare OLED device (∼30 lm/W at 100 cd/m2) [Fig. 7]. The CIE coordinate for the down-converted light was (0.302, 0.529). 4.2.White Light Using Yellow-Red Phosphor MixturePreviously, we demonstrated that incorporation of a red-emitting second phosphor with the yellow phosphor in the down-converting layer improved both the average CRI value and CIE coordinates for an iLED source.19 In this research, a mixture of the red and yellow phosphors in a silicone matrix was used to improve the quality of the down-converted white light from MC-OLED and NC-OLED devices. The OLEDs were operated at currents ranging from 10 to 50 μA. A phosphor down-conversion layer was prepared using 30 mg of phosphor (yellow and red with a weight ratio 2:1) mixed in 150 mg of silicone which was manually doctor-bladed directly onto the OLED device. Figures 8, 8 show the down-converted white light spectra with different current values for NC and MC devices, respectively. The relative efficacy of white compared to blue light from the MC-OLED device was a factor of ∼1.5× enhancement, as shown in Fig. 8. No efficacy improvement was observed for NC devices with a yellow and red mixture, consistent with the results from only the yellow phosphor device [Fig. 7]. The down-converted light exhibited CIE coordinates of (0.377, 0.436) and (0.399, 0.473) for NC- and MC-OLED devices, respectively. The CRI values were 82 and 76 for NC and MC OLED devices, respectively. Due to the broad blue emission from NC-OLED compared to MC-OLED devices, the CRI value is higher for the NC device. The CRI values for the 15 reference color standards (CRI1 to CRI15) from two different down-converted white lights using MC and NC are shown in Fig. 8. It is observed that the CRI (also called R9) value for white light from the MC device is higher than that from the NC device. Note that although the CRI value is higher for the MC device, the relative luminance efficacy (lm/W) was not improved from NC devices. In order to study this further, we change the weight ratio in the mixture from 2:1 to 1:1 for yellow to red phosphors, while the CRI value was increased to 86 for the 1:1 ratio of yellow to red phosphor (results not shown here). There is no improvement in luminance efficacy. Fig. 8Down-converted spectra from (a) MC and (b) NC device with a 2:1 weight ratio yellow: red phosphor mixture in a 30 mg/150 mg film. (c) Relative efficacy (lumens/OLED input power–Watt) versus device current for blue and down-converted white light from an MC-OLED with yellow and red phosphors. (d) Color rendering index values of 1 and 15 (CRI1 to CRI15) standard colors for down-converted white light from either a MC- or NC-OLED device.  5.ConclusionsDown-conversion of blue light from OLEDs to yield a high quality white light was demonstrated using yellow and mixtures of yellow and red emitting phosphors in a silicone host. OLEDs with and without a two quarter wave stack microcavity were tested. The weight of the phosphor in the silicone was varied to optimize the quality of light and luminance efficacy. An average CRI value of more than 80 was found for white light generated from an MC-OLED down-converted using a 2:1 red:yellow phosphor mixture (30 mg) in 150 mg silicone matrix. The luminance efficacy (lm/W) was increased by a factor of 2 for white versus blue light when an MC-OLED device was down-converted using a 30 mg/150 mg yellow phosphor/silicone layer. AcknowledgmentsThis work was supported by the U.S. Department of Energy, Grant No. DE-FC26-06NT42855. We gratefully acknowledge assistance from the Major Analytical Instrument Center (MAIC), Particle Engineering Research Center (PERC), and MicroFabritech, the University of Florida for characterization data and analyses. We thank Dr. Mark Davidson, Dr. Lei Qian, and Dr. Sean Jones for help in setting up and calibrating the optical bench and for valuable discussions. ReferencesA. Bergh, G. Craford, A. Duggal, and R. Haitz,

“The promise and challenge of solid-state lighting,”

Phys. Today, 54 42

–47

(2001). http://dx.doi.org/10.1063/1.1445547 Google Scholar

L. Qian, D. Bera, and P. H. Holloway,

“White light emission from single layer poly (n-vinylcarbazole) polymeric light-emitting devices by mixing singlet and triplet excimer emissions,”

J. Chem. Phys., 127 244707

(2007). http://dx.doi.org/10.1063/1.2813431 Google Scholar

R. W. Meerheim, G. He, M. Pfeiffer, and K. Leo,

“Highly efficient organic light emitting diodes (OLED) for displays and lighting,”

Proc. SPIE, 6192 22

(2006). http://dx.doi.org/10.1117/12.666905 Google Scholar

J. K. Sheu, S. J. Chang, C. H. Kuo, Y. K. Su, L. W. Wu, Y. C. Lin, W. C. Lai, J. M. Tsai, G. C. Chi, and R. K. Wu,

“White-light emission from near UV InGaN-GaN LED chip precoated with blue/green/red phosphors,”

IEEE Photon. Technol. Lett., 15 18

–20

(2003). http://dx.doi.org/10.1109/LPT.2002.805852 Google Scholar

C. H. Kuo, J. K. Sheu, S. J. Chang, Y. K. Su, L. W. Wu, J. M. Tsai, C. H. Liu, and R. K. Wu,

“n-UV plus blue/green/red white light emitting diode lamps,”

Jpn. J. Appl. Phys., Part 1, 42 2284

–2287

(2003). http://dx.doi.org/10.1143/JJAP.42.2284 Google Scholar

J. S. Kim, P. E. Jeon, Y. H. Park, J. C. Choi, H. L. Park, G. C. Kim, and T. W. Kim,

“White-light generation through ultraviolet-emitting diode and white-emitting phosphor,”

Appl. Phys. Lett., 85 3696

–3698

(2004). http://dx.doi.org/10.1063/1.1808501 Google Scholar

I. W. Park, H. J. Lee, J. S. Yoo, and C. K. Choi,

“Optical characteristics of xSrO center dot yAl(2)O(3) : Eu phosphors excited by ultraviolet light emitting diodes,”

Korean J. Chem. Eng., 24 294

–298

(2007). http://dx.doi.org/10.1007/s11814-007-5059-3 Google Scholar

J. K. Park, C. H. Kim, S. H. Park, H. D. Park, and S. Y. Choi,

“Application of strontium silicate yellow phosphor for white light-emitting diodes,”

Appl. Phys. Lett., 84 1647

–1649

(2004). http://dx.doi.org/10.1063/1.1667620 Google Scholar

R. Mueller-Mach, G. O. Mueller, M. R. Krames, and T. Trottier,

“High-power phosphor-converted light-emitting diodes based on III-nitrides,”

IEEE J. Sel. Top. Quantum Electron., 8 339

–345

(2002). http://dx.doi.org/10.1109/2944.999189 Google Scholar

F. Hide, P. Kozodoy, S. P. DenBaars, and A. J. Heeger,

“White light from InGaN/conjugated polymer hybrid light-emitting diodes,”

Appl. Phys. Lett., 70 2664

–2666

(1997). http://dx.doi.org/10.1063/1.118989 Google Scholar

A. R. Duggal, J. J. Shiang, D. F. Foust, L. G. Turner, W. F. Nealon, and J. C. Bortscheller,

“Large Area White OLEDs,”

SID Int. Symp. Digest Tech. Papers, 36 28

–31

(2005). http://dx.doi.org/10.1889/1.2036427 Google Scholar

B. C. Krummacher, V. E. Choong, M. K. Mathai, S. A. Choulis, F. So, F. Jermann, T. Fiedler, and M. Zachau,

“Highly efficient white organic light-emitting diode,”

Appl. Phys. Lett., 88 113506

(2006). http://dx.doi.org/10.1063/1.2186080 Google Scholar

A. R. Duggal, J. J. Shiang, C. M. Heller, and D. F. Foust,

“Organic light-emitting devices for illumination quality white light,”

Appl. Phys. Lett., 80 3470

–3472

(2002). http://dx.doi.org/10.1063/1.1478786 Google Scholar

W. Y. Ji, L. T. Zhang, R. X. Gao, L. M. Zhang, W. F. Xie, H. Z. Zhang, and B. Li,

“Top-emitting white organic light-emitting devices with down-conversion phosphors: Theory and experiment,”

Opt. Express, 16 15489

–15494

(2008). http://dx.doi.org/10.1364/OE.16.015489 Google Scholar

P. Schlotter, R. Schmidt, and J. Schneider,

“Luminescence conversion of blue light emitting diodes,”

Appl. Phys. A, 64 417

–418

(1997). http://dx.doi.org/10.1007/s003390050498 Google Scholar

M. R. Krames, J. B. D. Collins, N. F. Gardner, W. Gotz, C. H. Lowery, M. Ludowise, P. S. Martin, G. Mueller, R. Mueller-Mach, S. Rudaz, D. A. Steigerwald, S. A. Stockman, and J. J. Wierer,

“High-power III-nitride emitters for solid-state lighting,”

Phys. Status Solidi A, 192 237

–245

(2002). http://dx.doi.org/10.1002/1521-396X(200208)192:2<237::AID-PSSA237>3.0.CO;2-I Google Scholar

H. S. Chen, C. K. Hsu, and H. Y. Hong,

“InGaN-CdSe-ZnSe quantum dots white LEDs,”

IEEE Photon. Technol. Lett., 18 193

–195

(2006). http://dx.doi.org/10.1109/LPT.2005.859540 Google Scholar

W. Chung, K. Park, H. J. Yu, J. Kim, B. H. Chun, and S. H. Kim,

“White emission using mixtures of CdSe quantum dots and PMMA as a phosphor,”

Opt. Mater., 32 515

–521

(2010). http://dx.doi.org/10.1016/j.optmat.2009.11.005 Google Scholar

D. Bera, S. Maslov, L. Qian, and P. H. Holloway,

“On enhamcement of quality of down-converted white light,”

J. Photon. Energy, 1 016501

(2011). http://dx.doi.org/10.1117/1.3555421 Google Scholar

J. Lee, N. Chopra, and F. So,

“Cavity effects on light extraction in organic light emitting devices,”

Appl. Phys. Lett., 92 033303

(2008). http://dx.doi.org/10.1063/1.2830820 Google Scholar

N. Chopra, J. Lee, Y. Zheng, S. H. Eom, J. G. Xue, and F. So,

“High efficiency blue phosphorescent organic light-emitting device,”

Appl. Phys. Lett., 93 143307

(2008). http://dx.doi.org/10.1063/1.3000382 Google Scholar

D. Bera, S. Maslov, L. Qian, J.-S. Yoo, and P. H. Holloway,

“Optimization of yellow phosphor layer for down-conversion of blue to white light,”

J. Disp. Technol., 6

(12), 645

–651

(2010). http://dx.doi.org/10.1109/JDT.2010.2064284 Google Scholar

C. D. Muller, A. Falcou, N. Reckefuss, M. Rojahn, V. Wiederhirn, P. Rudati, H. Frohne, O. Nuyken, H. Becker, and K. Meerholz,

“Multi-colour organic light-emitting displays by solution processing,”

Nature (London), 421 829

–833

(2003). http://dx.doi.org/10.1038/nature01390 Google Scholar

M. Shtein, J. Mapel, J. B. Benziger, and S. R. Forrest,

“Effects of film morphology and gate dielectric surface preparation on the electrical characteristics of organic-vapor-phase-deposited pentacene thin-film transistors,”

Appl. Phys. Lett., 81 268

–270

(2002). http://dx.doi.org/10.1063/1.1491009 Google Scholar

Z. Q. Gao, W. Y. Lai, T. C. Wong, C. S. Lee, I. Bello, and S. T. Lee,

“Organic electroluminescent devices by high-temperature processing and crystalline hole transporting layer,”

Appl. Phys. Lett., 74 3269

–3271

(1999). http://dx.doi.org/10.1063/1.123316 Google Scholar

J. Lee, N. Chopra, D. Bera, S. Maslov, S-H Eom, Y. Zheng, P. Holloway, J. Xue, and F. So,

“Down-Conversion white organic light-emitting diodes using microcavity structure,”

Adv. Energy Mat., 1

(2), 174

–178

(2011). http://dx.doi.org/10.1002/aenm.201000014 Google Scholar

BiographyDebasis Bera is currently working as an engineer in Philips Lumileds, San Jose, California. He was a postdoctoral associate in the Department of Materials Science and Engineering in University of Florida. He received his MTech degree in materials science and engineering from Indian Institute of Technology Bombay (India) in 2002 and his PhD degree in mechanical, materials and aerospace engineering, University of Central Florida (Orlando, USA) in 2005. He has co-authored 1 book, 2 book chapters, over 30 journal publications, and 1 issued patent. He specializes in nanomaterials, optical materials, and down-converted white light. Franky So is a University of Florida Research Foundation professor in the Department of Materials Science and Engineering at the University of Florida. He received his PhD degree in electrical engineering from the University of Southern California. He is a Fellow of SPIE. His research interest is in the area of OLEDs, organic photovoltaics, and infrared sensors. He is an associate editor of IEEE's Journal of Display Technology and Journal of Photovoltaics, SPIE's Journal of Photonics for Energy and Materials Science, and Engineering Reports. He has over 70 journal publications, 60 issued patents, and another 30 patent applications pending. Paul Holloway is a distinguished professor and the Ellis D. Verink, Jr. professor of materials science and engineering at the University of Florida, Gainesville. He is also the director of MICROFABRITECH, an interdisciplinary materials research program at the University of Florida. He received his PhD in 1972 from the Rensselaer Polytechnic Institute. He has also worked at General Electric and at Sandia National Laboratory. His areas of research include electrical contacts to semiconductors, optical emission from inorganic and organic thin films and powders, and synthesis and optical emission from nanophosphors. |